· FabLab Westharima Team · 3D Printer · 4 min read

First Attempt at Making Akabeko – Using Fusion360/3D Printer

3D printing akabeko (traditional Japanese toy) using Fusion360 form modeling. Complete guide from data creation to assembly and painting, including trial-and-error process and lessons learned.

I challenged myself to make an “akabeko” (a traditional Japanese bobblehead cow toy from Fukushima) using a 3D printer for the first time. To preserve the process, I’m documenting the “how-to,” “materials needed,” and “what I learned” as a reference for myself (details below).

Re-learning Fusion360 “Form Modeling”

When I tried to use Fusion360’s form modeling feature for the first time in six months, I couldn’t quite remember the operation flow or menu button locations. Even after I thought I understood it and started creating, I couldn’t achieve the ideal body shape, and while making minor adjustments, intersection errors occurred frequently (tears). Although I only output a few bodies, in Fusion360 it became a repetition of creating and deleting bodies.

To create the body I wanted, I re-studied form modeling once again using “Autodesk Fusion Masters Guide Basic Edition 3rd Revised Edition”. I realized the importance of consciously and continuously using software and features multiple times. Ah, when will I graduate from this textbook…

Required Items and Materials

For 3D Printer Use

- 3D printer

- Computer

- 3D CAD software

- Slicer software

- Filament

For Making Akabeko

- Sandpaper

- File

- Pin vise

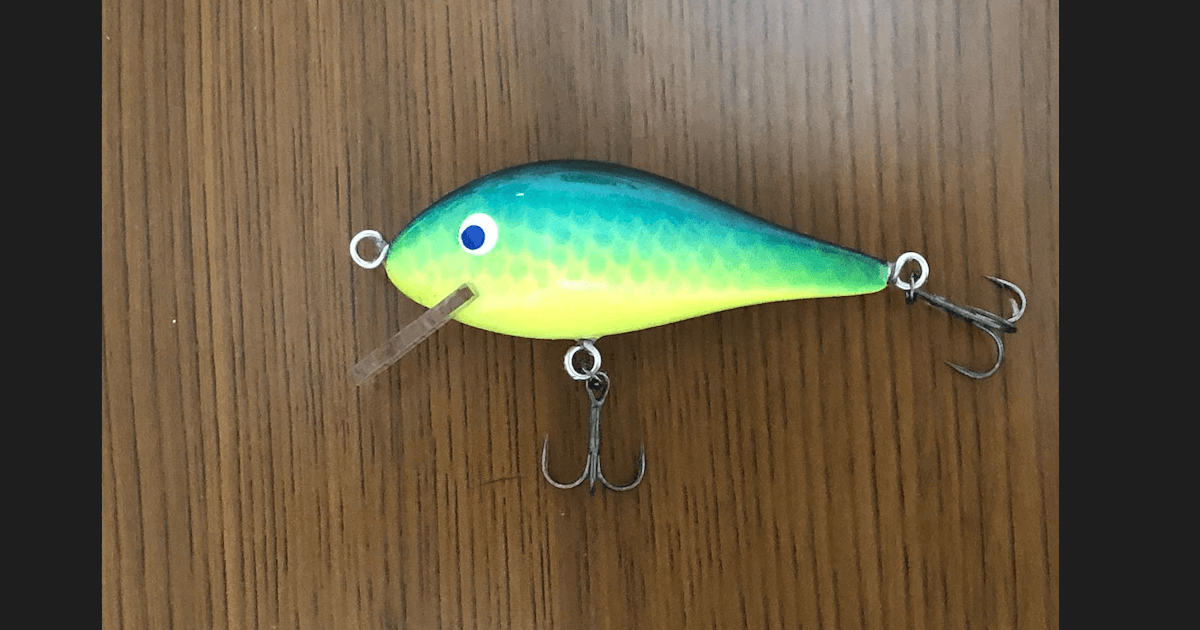

- Weight (any weight is OK, but I used several round fishing weights)

- Thread

- Super glue

- Posca markers

How to Make Akabeko - My Process

STEP 1: 3D Data Creation

Create data in 3D CAD software

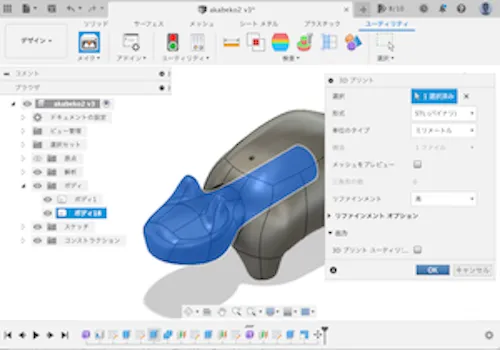

*Software used: “Fusion360” *Among several prototypes, I’ll introduce the body creation process that worked best.

[Creating Body and Legs]

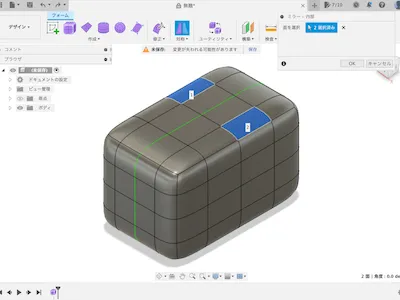

- First, create the base shape using “Create Form” → “Box”. *To create a symmetrical body, utilize the mirror function.

Utilize “Edit Form,” “Insert Edge,” “Subdivide,” etc. to create legs under the body.

Utilize “Edit Form,” “Insert Edge,” “Subdivide,” etc. to create legs under the body.  Repeat “Edit Form” to create rounded body and leg shapes.

Repeat “Edit Form” to create rounded body and leg shapes.

- Create internal structure Use “Shell” to hollow out the inside and create walls. (Reference: Create with a thickness that doesn’t cause errors.)

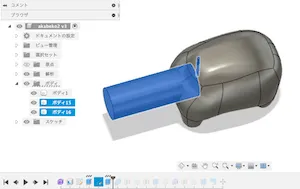

- Create two cylinders as new bodies for the neck and thread holes.

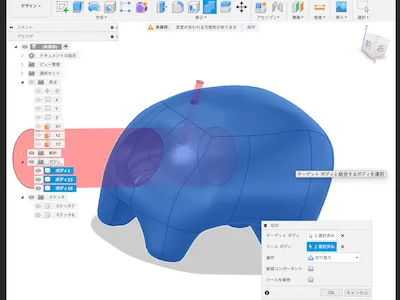

- Using the “Combine” function, cut out the “two cylinders” created in “3” from the body,

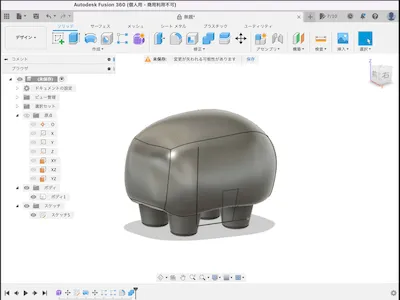

Body and legs shape completed

Body and legs shape completed

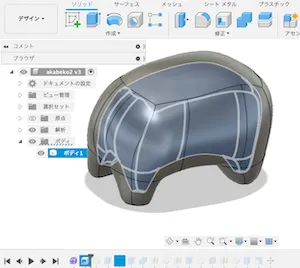

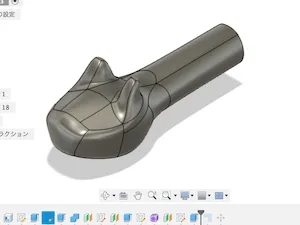

- Hide the body and legs, and start creating the head and neck body.

[Creating Head and Neck]

- First, create the base shape using “Create Form” → “Box”. *To create a symmetrical body, utilize the mirror function, then use “Edit Form,” “Insert Edge,” “Subdivide,” etc. (The neck is intentionally made longer. Plan to cut off unnecessary parts later)

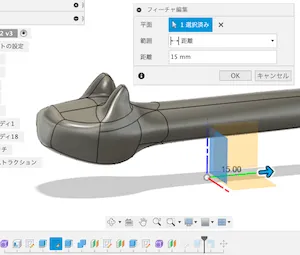

- Cut off unnecessary parts of the neck. *Utilize “Offset Plane” and “Extrude”.

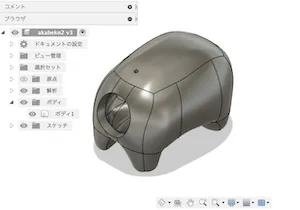

- Head and neck shape completed

When I hollowed out the head and neck with “Shell,” the shape collapsed during 3D printer output, so I abandoned the shell approach. Instead, I decided to address this by “changing the infill values in the next slicer settings process.”

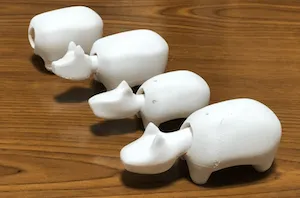

[Body Completed]

- Display both bodies and check & adjust the balance.

- If you want to change the body size, use the scale function.

STEP 2: STL File Export

Export file from 3D CAD software (STL format)

[In this case] In Fusion360 → “Utilities” → “Make” → “3D Print”, select each body and export in STL format.

STEP 3: Slicing Process

Convert to data format for 3D printer output (using slicer software)

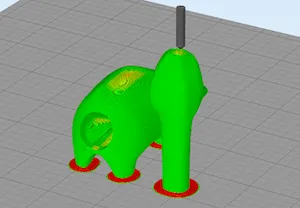

Software used: “Simplify3D” Based on lessons learned from test output, I added the following slicer settings and exported in gcode format.

[Head and neck orientation]… Changed to vertical [Additional feature - Skirt] … Red part in the diagram below. Set because the body peeled off the bed during test output. [Infill - Internal fill ratio] … Set to a small amount.

STEP 4: Load Data

Load slicer data into the 3D printer

STEP 5: Set Filament

Set material (filament) in the 3D printer

STEP 6: 3D Print Output

Output with 3D printer

STEP 7: Remove Object

Remove the 3D printed object from the 3D printer

After 3D printer output, remove the 3D object after the bed has cooled down.

STEP 8: Post-processing

Remove supports and unnecessary parts (deburring, sanding, etc.)

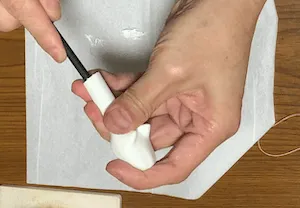

This time, to thread the string and insert the weight, I also removed the infill inside the neck.

STEP 9: Assembly

Assembly

- Put the weight in the neck and decide where to hang the neck from the body with thread.

- Drill a hole in the neck with a pin vise and hang it from the body with thread.

- Check if the head moves nicely (*If the movement is not good, repeat steps 1-3.)

- Fix the weight and thread with super glue

- Assembly

STEP 10: Painting

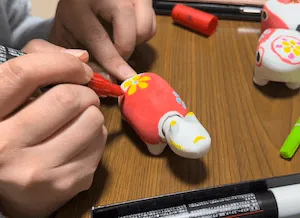

Painting

This time, painted with Posca markers

Completed!

Impressions

- When painting after assembly, the area around the neck was difficult to paint. I thought it would be safer to paint first and then assemble.

- I hadn’t used Fusion360’s “form modeling feature” for a while, and I struggled to remember the menu and button locations, among other things. I realized the importance of continuously using software and features.