· FabLab Westharima Team · 3D Printer · 6 min read

Bambu Lab P1S Review | Pros and Cons Found After Using 30 Rolls in 1 Month [Multi-Color 3D Printer]

An honest review of the Bambu Lab P1S + AMS based on real experience of continuous operation for one month, using 30 rolls of 1kg filament (total 30kg). Detailed explanation of practicality and important points for multi-color printing.

Bambu Lab P1S Review | Pros and Cons Found After Using 30 Rolls in 1 Month [Multi-Color 3D Printer]

Introduction

The Bambu Lab P1S + AMS has been gaining attention in the 3D printing world. This article provides an honest review of its advantages and disadvantages based on real experience of continuous operation for one month, using 30 rolls of 1kg filament (total 30kg). We will explain in detail the practicality and important points of multi-color printing.

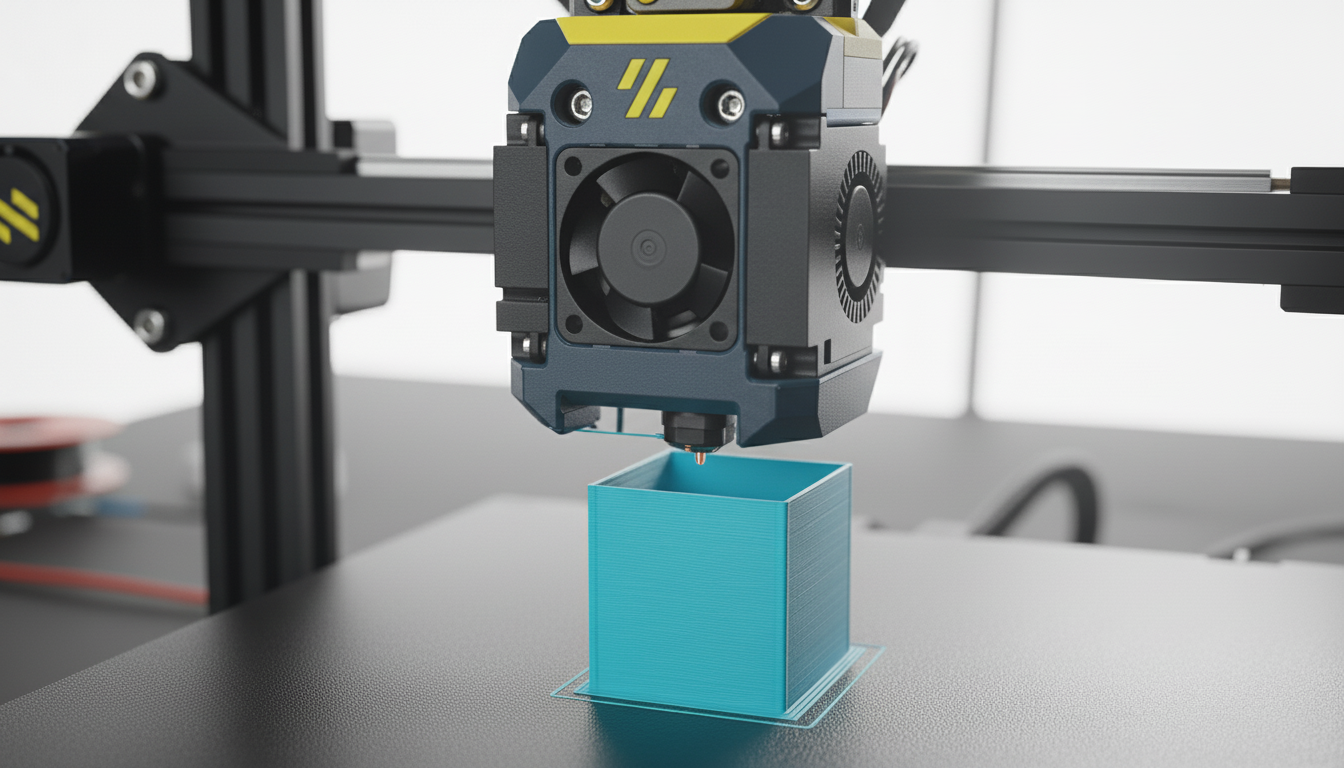

- Image (Work in Progress)

1. Operating Environment

- Model: Bambu Lab P1S (with AMS)

- Nozzle Diameter: 0.4mm (standard)

- Software: Bambu Studio (standard slicer)

- Usage Period: 1 month continuous operation (operated without turning off power)

- Usage Amount: 30 rolls of 1kg filament (total 30kg)

- Printing Contents: Continuous printing with same material and color filament using AMS function

- Printed Objects: Robot body parts

- Print Speed: Same as genuine slicer preset

- Material (Filament): Polymaker - PolyTerra PLA 1kg White 1.75mm diameter

- Purchase Date: Around late June 2025

- Price: Body + AMS set - List price approx. 140,000 yen, Actual price approx. 120,000 yen

2. Results of 1 Month Continuous Operation

Troubles:

- Operated without major printing troubles

- Used the 0.4mm nozzle that came with purchase, no nozzle clogging occurred

- As a mechanical trouble, filament broke inside AMS PTFE tube and error message wouldn’t disappear, which was concerning

- Build plate became dirty and adhesion weakened slightly (recovered after washing with neutral detergent)

Print Quality (subjective impression):

- Out of 30 rolls, there were no failures to speak of

- Layer pitch and surface roughness declined slightly, but not noticeably

- You might find it suspicious, but there were no failures and no interrupted prints

- Fine details were reproduced with sufficient accuracy

- Fit between parts was of sufficient quality

- No noticeable quality variation, stable output was obtained

Image (Output Sample)

3. Initial Setup

- Time from unboxing to start printing

- As fast as 15 minutes. About 1 hour if done slowly

- Setup Difficulty

- In my case, due to missing mounting parts, different higher quality parts without instructions were included, and it was difficult to understand how to attach them, which caused some confusion

- Connecting WiFi and installing the app was smooth

Features and Machine Specs of Bambu Lab P1S + AMS

Features

- Ready to use, setup completed in 15 minutes

- Enclosed chamber, supports various filaments including high-temperature materials

- Can connect up to 4 AMS units, 16-color multi-color modeling possible

- High completion level of hardware and software

- Maximum acceleration of 20,000 mm/s², prints Benchy in 18 minutes

- Built-in camera capable of remote monitoring and time-lapse photography

| machine spec | Description |

|---|---|

| Maximum Build Volume (WxDxH) | 256 x 256 x 256 mm³ |

| Nozzle Diameter | 0.4 mm (standard equipment, replaceable) |

| Maximum Nozzle Temperature | 300°C (required for high-temperature filament support) |

| Build Plate | Flexible PEI plate (magnetic, double-sided textured/smooth, required for detachability/maintenance) |

| Maximum Build Plate Temperature | 100°C (required for adhesion/warping prevention) |

| Filament Diameter | 1.75mm |

| Maximum Head Speed | 500 mm/s |

| Maximum Head Acceleration | 20 m/s² |

| Compatible Filaments | Recommended: PLA, PETG, TPU, PVA, PET, ABS, ASA Not recommended: PA, PC |

| Chamber Monitoring Camera | 1280 x 720 / 0.5fps Time-lapse (required for remote monitoring) |

| Filament Runout Sensor | Available (required for automatic detection) |

| Auto Bed Leveling | Available (required for Z-axis auto calibration) |

| Nozzle Auto Cleaning | Available (required for purge/wipe) |

| P1S Body Dimensions | 389 x 389 x 458 mm³ |

| Body Weight | 12.95kg |

| Total Weight (including AMS) | 21.60kg |

Advantages and Convenient Points of Bambu Lab P1S + AMS

In addition to printing 30 rolls of 1kg filament (total 30kg), we also used multi-color, and here are my honest impressions.

1. Continuous Operation and Failure Reduction During Night Output by AMS

This time, I used all the same color and type of filament. By using AMS, an option for Bambu Lab P1S, filament for 4 rolls is automatically replenished without manual replacement, so there’s no worry about running out of filament, and I could safely operate it unattended during long continuous operation and night output. Also, filament that was running low could be used up completely without waste.

2. Remarkable Stability and Reliability

I ran it continuously for one month without turning off the power and consumed 30 rolls of filament, but no major troubles occurred. This stability is a very important point for those considering commercial use or mass production.

3. High Stability by Using Genuine Parts

By not using third-party consumables and using genuine parts, I was able to use it comfortably with few troubles. Although initial investment is somewhat higher, using genuine parts is recommended considering long-term stability.

4. Easy Settings with Preset Utilization

When using genuine filament or filament registered in Bambu Studio presets, settings are very easy. If you use presets for slicing conditions and settings, output quality is sufficient.

5. Maintenance-Free Automation Features

Almost no fine settings or adjustments needed, very hassle-free:

- Auto Leveling Function: Bed leveling is automatic

- Automatic Nozzle Cleaning: Nozzle is automatically cleaned before printing

- Filament Drip Handling: No need to wipe filament drips from nozzle at print start

With these automation features, even beginners can achieve high-quality prints.

Disadvantages and Problems of Bambu Lab P1S + AMS

1. Filament Waste Due to Purge

The biggest challenge of multi-color printing is filament consumption due to purge.

What is Purge?

Purge is the operation of pushing out old color or foreign matter in the nozzle or hotend and replacing it with new filament. It’s essential when changing colors in multi-color mechanisms, and excess molten filament is discharged from the nozzle (commonly called “poop”).

- Purge is necessary right after start or every time color changes

- Frequent color changes result in wasteful filament consumption

- During purge, molten filament is discharged from the rear every time

2. Time Loss During Frequent Color Changes

- When color changes occur frequently, filament replacement takes time each time

- For complex designs using many colors, print time can increase significantly

3. Noise Problem

- Automatic adjustment sounds like leveling at print start are loud

- Operation noise is also quite loud, causing stress if you’re in the same room

- If placed on a low-strength table, vibration causes the desk to shake quite violently

Countermeasures for Disadvantages

Ways to Reduce Purge Waste

- Batch Printing Multiple Items: By printing multiple items together at once, purge waste per item can be relatively reduced

- Minimize Number of Colors: By designing with the minimum necessary number of colors, reduce the hassle and waste of filament replacement

Noise and Vibration Countermeasures

- Use Vibration-Damping Rubber: Place vibration-damping rubber under the device

- Install on Heavy Stand: Suppress vibration by installing on a sturdy and heavy stand

- Use Soundproof Box: Use a soundproof box or install in a separate room

- Devise Installation Location: Avoid bedrooms or living rooms, install in work rooms or storage areas

Summary: Who Should Use Bambu Lab P1S + AMS

Recommended For

- Those who prioritize stability and reliability: Track record of trouble-free operation for 1 month

- Those who want to reduce maintenance hassle: Abundant automation features

- Those who want to use genuine parts safely: Comfortable with combination of presets and genuine parts

- Beginners to intermediate users: High-quality printing possible without detailed settings

Use With Caution If

- Those who frequently print complex designs in multi-color: Large loss of time and filament due to purge

- Those who prioritize quietness: Noise and vibration countermeasures needed

- Those working in the same room: Noise may cause stress

Overall Rating

Bambu Lab P1S is a very well-completed 3D printer with excellent stability and automation features. By utilizing genuine parts and presets in particular, even beginners can easily achieve high-quality prints.

Although purge problems and noise in multi-color printing are concerns, it is sufficiently practical with countermeasures. The reliability of trouble-free operation even after using 30 rolls in one month is a major advantage not found in other printers.

For 3D printer beginners to intermediate users seeking a stable printing environment, this is a machine I can confidently recommend.

Keywords: Bambu Lab P1S, 3D Printer, Review, Multi-color Printing, AMS, Bambu Studio, 3D Printer Beginner, Stability, Purge Problem