· FabLab Westharima Team · DIY · 2 min read

Laser DIY: Making a Wall Clock | From Design to Processing with Fusion360

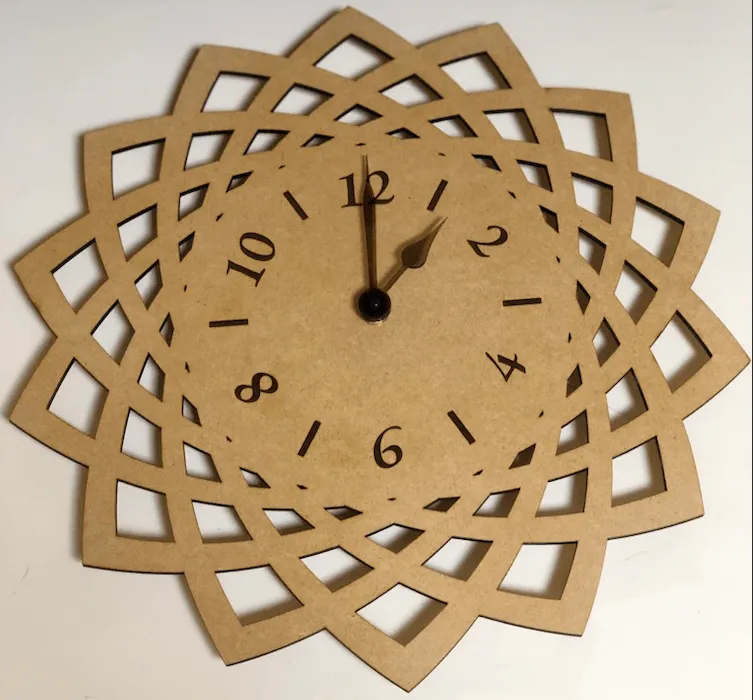

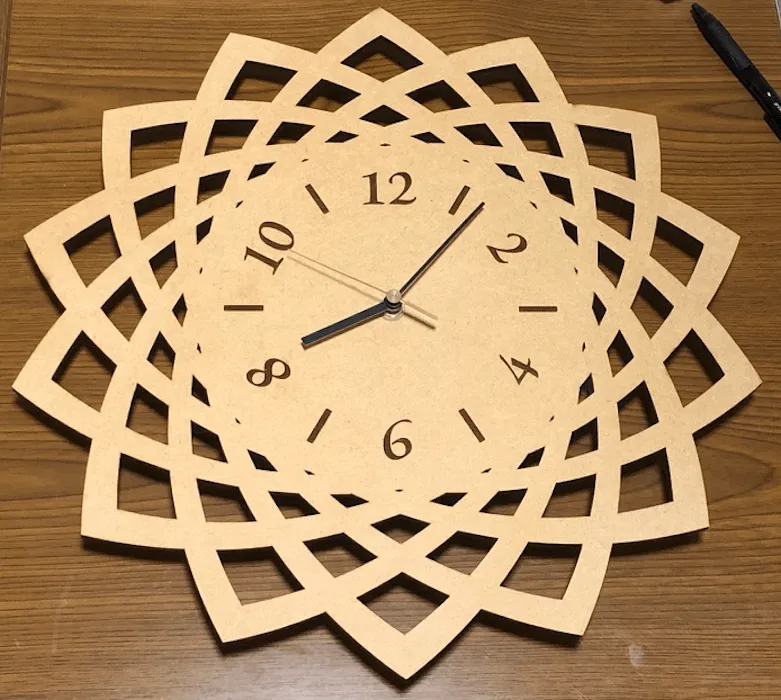

Creating an original wall clock with a laser cutter. Sharing the entire process from data creation in Fusion360, processing MDF and acrylic, assembly, and reflections after 2 years of use.

In 2019, I challenged my first making project (wall clock) with laser processing. I’ve compiled the method, materials, observations, and reflections as a memo for future reference.

【Creation Day 1】

- Created processing data in Fusion360 (I provided idea requirements. Data creation: requested to Shikamaru)

- Clock face: Cut MDF board with laser (clock face diameter: 38cm)

- Dial: Laser engraving

- Clock hands: Cut acrylic board (smoked transparent) with laser

- Assembly: Assembled parts from 1-3 with ‘Seria handmade clock kit movement’ (※Seria handmade clock kit hands not used as they don’t match self-made clock face size.)

That’s complete! Or so I thought for a moment. However, watching the clock at home for 1-2 days, the progress of hour and minute hands seemed strange. Confirmation and changes seemed necessary. My guess is the hands might be heavy, putting a load on the movement, so I decided to change.

【Creation Day 2】

- Clock hands: Changed to lighter ones

Afterwards, confirmed the clock hands advance according to time!

About 2 years later, it’s still active as a wall clock at home.

Materials

- MDF board (4mm thickness) ×1

- Acrylic board (smoked, 1mm thickness) ×1

- Handmade clock kit ×1

- Alkaline battery AA size ×1

Handmade clock kit purchased at Seria

Equipment

※This article was created in 2019. The equipment currently used at FabLab may differ.

- FABOOL Laser CO2 (CO2 laser cutter)

For currently available equipment, please check the Equipment List.

Observations and Reflections

- For a wall clock, 38cm diameter felt too large (※depends on room size)

- The kit hands from Seria are quite small (for desk clocks?)

- I didn’t have the skill to create processing data at that time, and Fusion360 software used by Shikamaru looked difficult at first glance

What is MDF Board?

Abbreviation for Medium Density Fiberboard, translated in Japanese as medium-density fiberboard, a board formed by adding synthetic resin to steamed and defibrated wood material chips

![[Free & Commercial Use OK] Illustration Material Collection Sites for Business Use](/_astro/656d0ea2b8478d70c95a8f897ecc44e3.Dunk5eRy.png)