· FabLab Westharima Team · DIY · 5 min read

Not Understanding Screw Sizes - Is That Strange?

From how to read hexagon socket bolt sizes to characteristics of various screws commonly seen at home centers. A screw selection guide for DIY beginners.

Not Understanding Screw Sizes - Is That Strange?

When helping with making things, my husband often asks me, “Go find and bring me a screw this size,” showing me the actual item. So I search through a case full of various sizes of screws mixed together and hand it to him, but it’s usually a slightly different size and he looks exasperated. Am I the only one who can’t tell screw sizes at a glance?

Common Exchange with My Husband

(Showing actual item) Bring me an M8 hexagon socket bolt like this

Hmm. Maybe this one… Here you go

That’s not it. That’s M6!

Sorry. But it’s hard to tell the size, you know. Plus, this case has all different sizes of screws mixed up.

You can tell just by looking! The sizes are totally different.

I can tell they’re different when I compare M6 and M8 sizes, but I can’t tell at a glance which one is M6 or M8. I think few people can tell…

I’ve repeated this exchange several times.

Besides, until a little while ago, I didn’t even know what “hexagon socket bolts” were!

Then, I’ll teach you how to read hexagon socket bolt sizes, so learn it.

Yes… sensei.

So, I’ve compiled what I learned about how to read hexagon socket bolt sizes and various screws commonly seen at home centers.

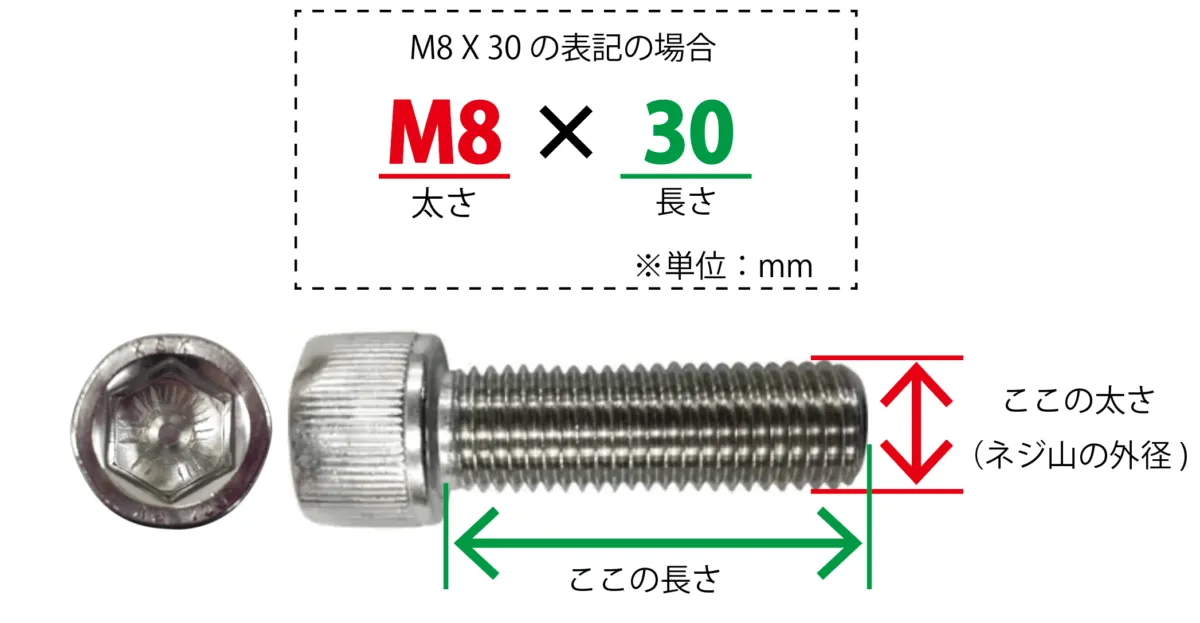

Hexagon Socket Bolt (Cap Screw) - How to Read Sizes

What is a Hexagon Socket Bolt? I Researched Again

- A bolt with a cylindrical head with a hexagonal hole.

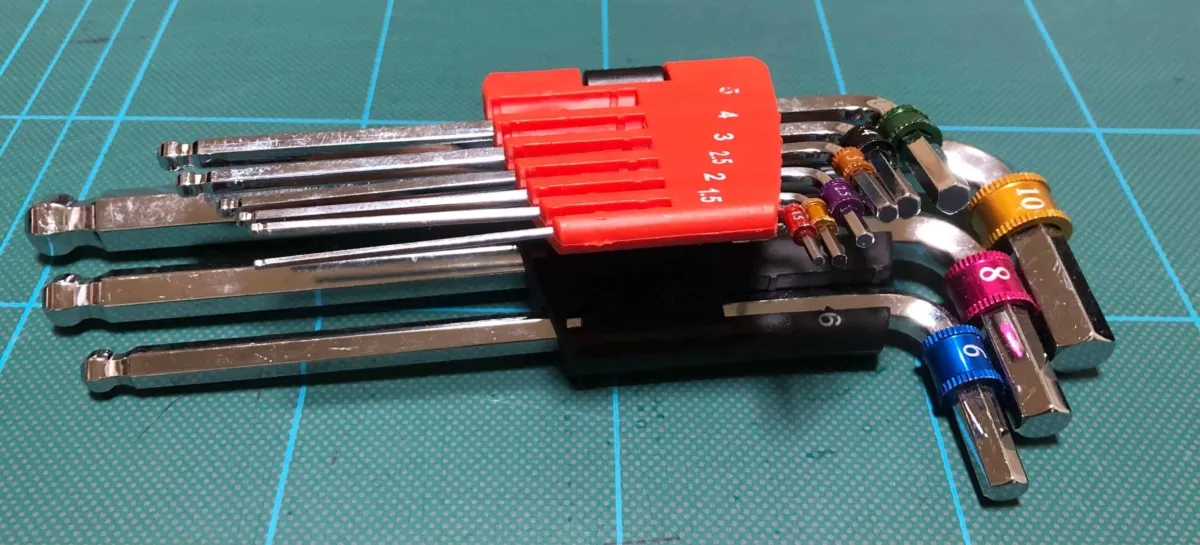

- For tightening, use a hex key (*see photo).

- Hexagon socket bolts have advantages such as high tightening force and are widely used. They are especially commonly used in machinery and electrical components.

Commonly Used Situations

- Furniture assembly (such as IKEA furniture)

- Bicycle and motorcycle maintenance

- Assembly and repair of mechanical equipment

- Machines such as 3D printers and laser cutters

Hex Key

A tool for tightening hexagon socket bolts (*the photo below shows one that’s active both at home and in the makerspace)

(Similar product introduction: Takagi TAKAGI Ball Point Hex Wrench Set 9-Piece)

Types of Screws Commonly Seen at Home Centers

When you go to the screw corner at home centers, there are so many types of screws that it’s confusing. Here, I’ve compiled commonly used screws for DIY in a table.

| Screw Type | Size Example | Characteristics | Main Uses |

|---|---|---|---|

| Tapping Screw (Coarse Thread) | φ3.8×25mm φ4.2×50mm | ・Pointed tip that drills its own hole ・Small pilot hole needed ・Thick, coarse thread ・Most common at home centers | ・Wood joining (shelves, tables, chairs) ・Mounting to drywall ・Fixing thin metal plates ・Furniture assembly/repair |

| Drill Screw | φ3.5×20mm φ4.0×32mm | ・Drill-shaped tip, no pilot hole needed ・Can be used on metal and wood ・Compatible with thin steel plates | ・Metal product assembly ・Wood and metal joining ・Storage shed and warehouse assembly |

| Flat Head Screw (Countersunk Screw) | M4×20mm M5×25mm | ・Flat inverted cone head ・Becomes flush with surface when tightened ・Clean appearance ・Phillips or slotted groove | ・Furniture surfaces ・Hinge mounting ・Cover fixing ・Places requiring flat finish |

| Pan Head Screw | M3×15mm M4×20mm | ・Round hemispherical head ・General and easy to use ・Phillips or slotted groove ・Head protrudes | ・Electrical products ・Plastic product fixing ・General assembly ・Places where appearance doesn’t matter |

| Truss Screw | M4×16mm M5×20mm | ・Thin, wide head ・Large contact area ・Doesn’t damage material ・Low head height | ・Thin plate fixing ・Sign mounting ・Plastic and resin ・Soft material fixing |

| Hex Bolt (Metric Thread) | M6×20mm M8×30mm | ・Marked as “M3,” “M4,” “M6,” “M8,” etc. ・Used with nuts ・Tightened with wrench or spanner ・High strength | ・Metal-to-metal fixing ・Machine assembly ・Joints requiring strength ・Places repeatedly disassembled/assembled |

| Machine Screw (Small Screw) | M2×8mm M3×12mm | ・Thin, precision screw ・Small sizes like M2, M3, M4 ・Tightened with Phillips screwdriver ・Available in pan or flat head | ・Computers and home appliances ・Plastic case fixing ・Circuit board mounting ・Precision equipment assembly |

How to Read Size Markings

Tapping Screw Type:

- φ3.8×25mm = diameter 3.8mm, length 25mm

Metric Thread Type:

- M6×20mm = Screw outer diameter approximately 6mm, length 20mm

- M = Metric thread (metric coarse thread)

Points for Choosing Screws

Differences by Material

| Material | Characteristics | Suitable Use Locations | Price |

|---|---|---|---|

| Steel (Zinc Plating) | ・Common and easy to obtain ・Rusts easily ・Sufficient strength | ・Indoor ・Low humidity places ・DIY furniture | Inexpensive |

| Stainless Steel | ・Rust-resistant ・High durability ・Somewhat difficult to process | ・Outdoor ・Kitchen/bathroom ・All water areas | Expensive |

| Brass | ・Conducts electricity ・High decorative quality ・Somewhat soft | ・Electrical wiring ・Decorative fittings ・Musical instrument repair | Expensive |

Head Groove Shapes

| Groove Shape | Characteristics | Required Tool | Commonly Seen Places |

|---|---|---|---|

| Phillips (+) | ・Most common ・Prone to cam-out (slipping from thread) ・Easy to use | Phillips screwdriver | ・Furniture ・Home appliances ・General DIY |

| Slotted (−) | ・Common in older products ・Can be tightened strongly ・Simple groove | Flathead screwdriver | ・Old furniture ・Electrical products ・Antiques |

| Hex Socket | ・Can be tightened strongly ・Hard to strip ・Compact tool | Hex key | ・Machinery ・Bicycles ・Assembled furniture |

| Torx (★) | ・Hard to cam out ・Handles high torque ・Recently increasing | Torx screwdriver | ・Automobiles ・Electronic devices ・Precision equipment |

Checklist When Choosing Screws

| Check Item | Confirmation Content | Selection Hints |

|---|---|---|

| 1. Purpose | What will it be used for? | ・For wood→Tapping screw ・For metal→Bolt & nut ・For plastic→Machine screw |

| 2. Size | Thickness and length? | ・Measure with calipers or measuring tape ・Aim for 2-3 times the board thickness |

| 3. Location | Where will it be mounted? | ・Outdoor/water areas→Stainless steel ・Indoor→Steel (zinc plating) is OK |

| 4. Strength | How much strength is needed? | ・High strength→Bolt & nut ・General DIY→Tapping screw |

| 5. Appearance | Don’t want it to stand out? | ・Flat finish→Flat head screw ・Don’t care→Pan head screw |

Summary & Impressions

- I haven’t talked about “not understanding how to read screw sizes” with anyone other than maker types, so my question remains unresolved.

- When you go to home centers, there are really so many screws that it’s confusing at first. But once you understand the purpose, it became easier to choose.

- Tapping screws need a small pilot hole, so I found them easy to use as a DIY beginner.

About Hexagon Socket Bolts

- I first saw them after getting married.

- My husband and his colleague said, “I wish we could buy more varieties of hexagon socket bolts at home centers.”

- According to my husband and his colleague (mechanical engineers), “Hexagon socket bolts are excellent screws that are hard to strip the head,” “The tool (hex key) is compact and easy to carry,” and “Easy to obtain.”

My husband told me he would explain the main screws for 30 minutes to an hour sometime soon. I thought I would understand everything about screws in just that one lecture, but he said, “It will take six months to understand everything about screws.” The world of screws is deep.

Additional note: After writing this article, I’ve been stopping more often at the screw corner at home centers. I feel like I’ve grown a little, now being able to recognize “Oh, this is a tapping screw” and “This is a flat head screw.” I hope this can be helpful for those struggling with screw selection.

![[Free & Commercial Use OK] Illustration Material Collection Sites for Business Use](/_astro/656d0ea2b8478d70c95a8f897ecc44e3.Dunk5eRy.png)