3D Printer Basic Operation Manual

What You Need

| Item | Details | Reference Price |

|---|---|---|

| 3D Printer Body | FDM type, pre-assembled recommended | $150 - $750 |

| Computer | General laptop is sufficient | Existing PC is OK |

| CAD Software | For 3D data creation | Free - Paid |

| Slicer Software | Converts 3D data to G-code | Free |

| Filament (Material) | PLA recommended for beginners | $15 - $30 per 1kg |

| Tools | Spatula, file, nippers, etc. | $15 - $40 |

Basic Operation Flow

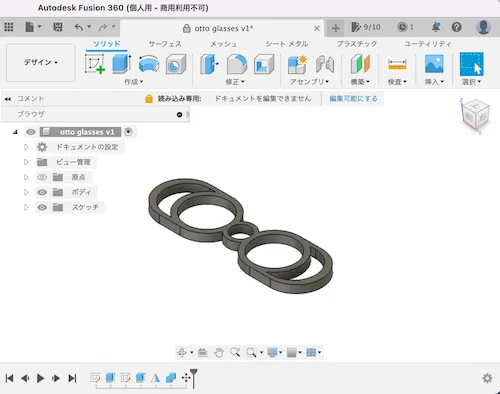

STEP 1: Prepare 3D Data

Prepare 3D data in STL format.

- Download: Get STL files from Thingiverse, Printables, etc.

- Create with CAD: Design using Fusion 360, Tinkercad, etc.

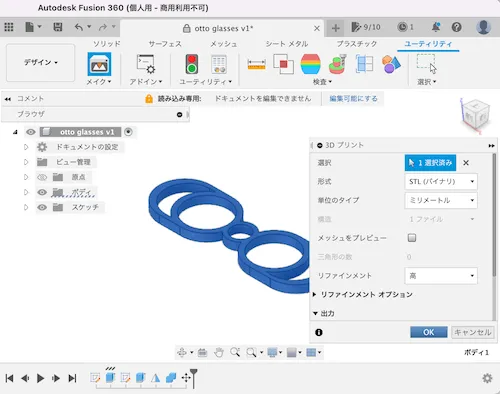

STEP 2: Export in STL Format

- If downloaded: Find and use STL file from files

- If created in CAD: Save in STL format using export function

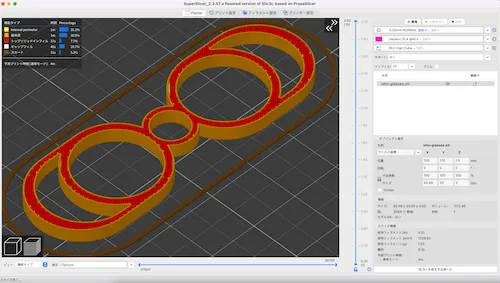

STEP 3: Convert to G-code with Slicer Software

Use slicer software to convert STL data to G-code (.gcode format).

⚠️ Slicer settings determine 80% of output quality

Main Settings

| Item | Recommended (Beginners) | Description |

|---|---|---|

| Layer Height | 0.2mm | Thickness of one layer |

| Infill Density | 15-20% | Internal fill rate |

| Print Speed | 50mm/s | Head movement speed |

| Nozzle Temp | 200°C (PLA) | Follow filament recommended value |

| Bed Temp | 60°C (PLA) | Follow filament recommended value |

| Support Material | As needed | Tree support is easy to remove |

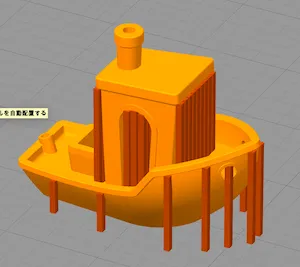

Support Material Example

|  |

|---|---|

| Without support | With support (brown parts, remove after printing) |

STEP 4: Transfer G-code to Printer

Save G-code to USB memory/SD card and insert into printer.

STEP 5: Set Filament

- Set material on filament holder

- Feed through to nozzle (many printers have auto-load function)

⚠️ Filament is humidity-sensitive, store in airtight container with desiccant after use

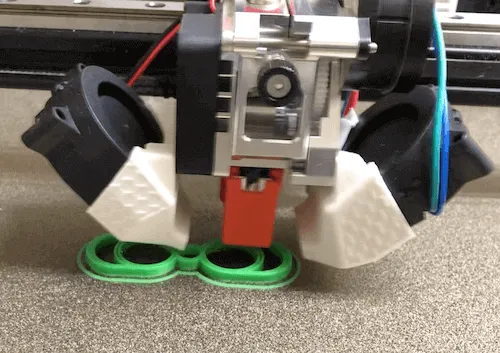

STEP 6: Bed Leveling

Adjust distance between print bed (platform) and nozzle.

- Too close: Nozzle clogs, damages bed

- Too far: Filament doesn’t adhere and fails

⚠️ Use auto-leveling if available. For manual, one sheet of paper gap as guide.

STEP 7: Start Printing

Start printing from printer screen.

Print time guide:

- Small items: 30 min - 2 hours

- Medium: 3-8 hours

- Large: 10+ hours

⚠️ Check first few layers, if OK then leave to printer. Avoid going out during long prints.

STEP 8: Remove Modeled Object

- Wait for bed to cool after printing (5-10 minutes)

- Carefully remove with spatula or scraper

STEP 9: Finishing

- Remove support material with nippers

- Sand with file as needed

Troubleshooting

| Failure Type | Symptom | Solution |

|---|---|---|

| First layer won’t adhere | Filament doesn’t stick to bed, becomes stringy | ・Re-adjust bed leveling (one paper gap) ・Raise bed temperature (60°C for PLA) ・Clean bed with alcohol |

| Peels during printing | Object peels from bed | ・Raise bed temperature ・Weaken cooling fan (0% for first few layers) ・Add brim (base) |

| Filament runout | Filament runs out mid-print | ・Check remaining amount before printing ・Check required amount in slicer |

| Filament tangling | Filament stops feeding mid-print | ・Secure through spool hole after use ・Check spool can rotate freely |

| Stringing | Spider web-like strings between objects | ・Lower nozzle temp by 5-10°C ・Enable retraction in slicer |

| Layer shifting | Layers shift or steps appear | ・Tighten printer belts ・Lower print speed (to ~40mm/s) |

| Nozzle clogging | Filament won’t come out | ・Dry filament ・Raise nozzle temp and clean ・Replace nozzle |

Precautions

| Item | Note |

|---|---|

| Modeling Size | Check printer’s maximum size. Divide if too large |

| Time | Even small items take several hours. Plan with margin |

| Copyright | Be careful of copyright for character data, etc. |

| Safety | Manufacturing weapons or dangerous items is illegal |

| Heat/Strength | PLA deforms above 60°C. Use ABS or PETG if heat resistance needed |

| Ventilation | ABS emits odor and trace harmful substances, ventilate |

Related Links

Beginner’s Guide

Resources

- Thingiverse - 3D data download

- Printables - 3D data download

- UltiMaker Cura - Slicer software