CNC Machining Collaborative Production with KDU

CNC Machining Collaborative Production with KDU

In fiscal year 2023, we collaborated with students and faculty from Kobe Design University (KDU) to jointly produce CNC Machining (Digico-MILL48) Version 6. With excellent precision and finish, we completed a machine filled with memories and dedication!

- Video:

- Making Movie

- Video Production: Professor Sowa, Kobe Design University

1. Research or Activity Objectives

1-1) Theme

- Building a Kobe Design University-style digital fabrication environment through collaboration with FabLab

1-2) Research or Activity Objectives (Overview)

This research aims to collaborate with FabLab to develop digital fabrication (DF) equipment and establish and disseminate a Kobe Design University-style DF educational environment. In recent years, as DF technology has advanced and been introduced at various universities, problems with the uniform adoption of low-cost equipment have also been identified. This research aims to develop educational CNC equipment with high precision and reliability that can be operated long-term, and to create a unique design education model by collaborating with local resources and human resources, thereby differentiating from other universities.

1-3) Background Leading to This Research or Activity Plan

In recent years, digital fabrication (DF) technology has been increasingly introduced at art universities. As DF equipment advances and becomes less expensive, many educational institutions tend to adopt cost-efficient, low-cost overseas DF equipment. This sometimes presents challenges in terms of educational effectiveness. Meanwhile, FabLab Westharima in Japan has developed low-cost CNC equipment with performance exceeding that of overseas products. Based on this, Kobe Design University is fundamentally reviewing its DF equipment introduction and aims to realize its own unique design and educational model by designing and manufacturing equipment themselves.

In this project, by inviting Kazunari Takeda, representative of FabLab Westharima, and having faculty and students jointly develop CNC equipment, we aim to build a practical DF equipment environment. Through this initiative, Kobe Design University aims to establish an advanced DF education model through international collaboration and widely disseminate its achievements.

2. Participants (In no particular order)

Kobe Design University

- Professor Noburu Miake

- Professor Nao Hiruta

- Professor Akinori Tagashira

- Professor Junichi Kanebako

- Professor Tomohiro Hata

- Tsukiko Fukui, Laboratory Assistant

- Satsuki Fujii, Laboratory Assistant

- Izumi, Machine Management Staff

- Student Volunteers

FabLab Westharima (External Instructors)

- Kazunari Takeda

- Hiroe Takeda

3. Developers

Kazunari Takeda

- Role: Overall production, mechanical/electrical/control design and fabrication

- Background: Mechanical Engineer

- Previous Positions:

- Mitsubishi Electric Engineer

- RIKEN (Harima) (SPring-8) Engineering Team

- Current Position: Digico, LLC CEO & FabLab Westharima Founder

4. Machine Specifications

| Machine spec | Description |

|---|---|

| Compatible Materials | Wood, machinable materials (acrylic, polycarbonate, PVC, etc), aluminum |

| Work Area | Approx. 1300 mm(w) x 2500 mm (L) x 150 mm (H) |

| Feed rate | 1-3000 mm/min |

| Spindle speed | max 18000 r/min |

| Control Board | HICON Integra mill |

| Control Software | Mach4 |

| Design Software | Fusion360 (CAD) for design |

5. Parts Procurement

| Title | Where to purchase |

|---|---|

| Mechanical Parts | MISUMI |

| Custom Parts | Proto design, MISUMI Meviy, Kobe Design University, Digico, LLC |

| Linear Guides & Ball Screws | THK, MISUMI, OZAK Seiko |

| Electrical & Control Components | AliExpress, VITAL system, HICON, GECKODRIVE |

6. Project Period

April 2023 - March 2024

7. Build Process for Digico-MILL48 Version 6

- Frame welding (semi-automatic welding & TIG)

- Frame painting

- Frame assembly

- Parts assembly

- Linear rail and ball screw installation

- Gantry installation

- Z-axis installation

- Distribution panel creation

- Wiring connection

- Machine assembly finishing

- Control software configuration

- Test run and precision verification

- Full operation

8. Results

March 2024

We completed one large CNC machining center filled with the sweat and various memories of students and faculty. We look forward to the creation of various designs and works using this CNC machining center in the future.

February 2025

About one year has passed since the large CNC began operation. According to inquiries, it has been operating daily without breaking a single end mill. In an environment used by many students, having no accidents whatsoever is remarkable. This is the result of thorough instruction on safety training and careful attention during training (tool path creation, machine operation, origin setting, etc.), which makes us very happy.

February 2025 / Chaos 2025

At Kobe Design University (KDU) graduation exhibition “Chaos 2025,” works created with the jointly produced large CNC machining center were exhibited!

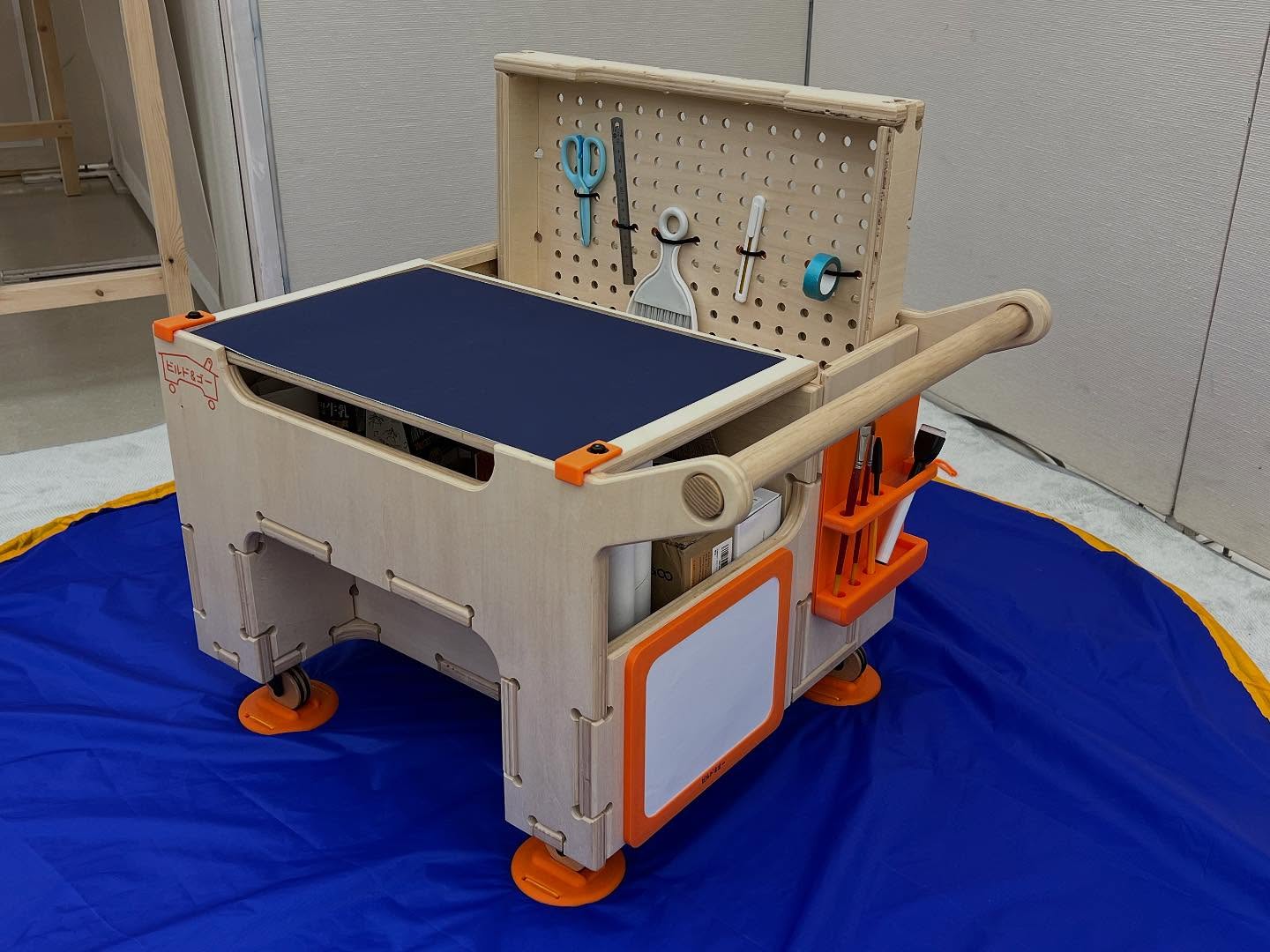

”Build & Go”

- Creator: Ayano Enma

- Overview: A product that fosters children’s spontaneity / A craft kit aligned with Japanese living environments and modern lifestyles

- Enma was also a participant in the CNC collaborative production project, practicing “making with what we made”

“Fit the Chair”

- Creator: Yuuki Okamoto

- Overview: A learning chair that can be assembled with only tools gentle on children’s hands