· FabLab Westharima Team · Laser Cutter · 4 min read

Safe Use of Laser Cutters | Basic Rules to Prevent Fire and Accidents

Explaining safety measures and basic rules when using laser cutters. Summarizing essential items to follow to prevent fire and health hazards.

Safe Use of Laser Cutters | Basic Rules to Prevent Fire and Accidents

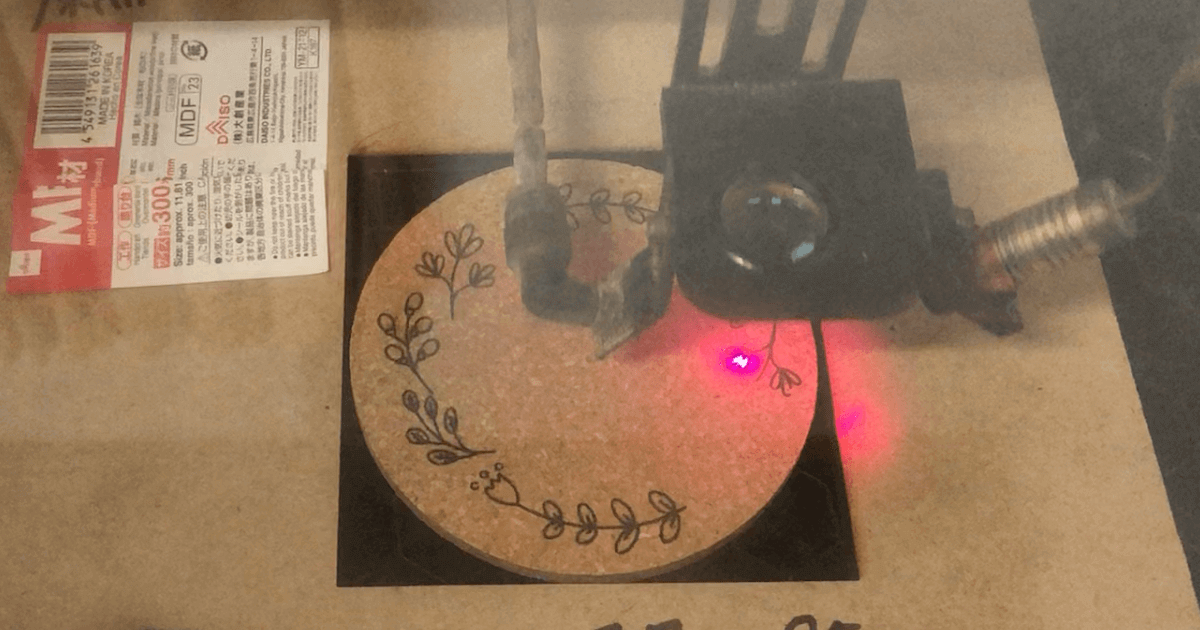

Laser cutters are convenient and powerful tools, but using them incorrectly can lead to fire, health hazards, and machine damage. This article explains basic rules that must absolutely be followed to use laser cutters safely.

Basics for Safe Use

Safe use of laser cutters is the top priority. Before starting actual operation, be sure to check the following precautions.

Fire Prevention is Top Priority

⚠️Never leave the machine during processing

- Processing materials may burn in unexpected ways during laser processing.

- Especially when parameters are high or materials have flammable paint or coating, fire may occur.

- Looking at smartphone or doing other work is absolutely prohibited. Fire can spread in seconds.

- Stand in front of machine during processing and constantly monitor processing status.

- If you sense danger of ignition or abnormality, promptly press STOP button and stop machine. Check if there is fire.

Examples of ignition danger or abnormality

- Sensing unusual movement or abnormality

- Larger smoke than usual

- Abnormal sound

- Visible sparks or flames

- Burnt smell (not normal laser processing odor, but intense smell)

⚠️Keep Fire Extinguisher Ready

- Always place fire extinguisher in processing space.

- If fire occurs, combustion continues even after stopping laser.

- Need to extinguish immediately with fire extinguisher. When using laser cutter, always place fire extinguisher within reach.

⚠️Smoke Management

- If exhaust duct is not functioning properly, large amount of smoke fills room during processing, reducing visibility.

- Even if fire occurs during processing, there is danger of not being visible due to smoke. Check that exhaust is functioning properly before processing.

Prohibited Materials and Dangers

⚠️Materials that must absolutely not be processed

There are many materials that cannot be laser processed. Processing these by mistake causes machine failure or fire.

| Material | Reason | Danger |

|---|---|---|

| Polyvinyl Chloride (PVC) | Produces hydrogen chloride gas when laser processed | Toxic gas generation, corrosion |

| Polycarbonate | Expands, deforms, burns at high temperature | Fire, machine damage |

| Fiber Reinforced Plastic (FRP) | Decomposes, burns at high temperature | Fire, toxic gas generation |

| All transparent hard plastics | High possibility of being vinyl chloride | Toxic gas generation |

| Unknown materials | Cannot process due to unknown composition | Unpredictable danger |

| Mirror-finished or plated items | Laser reflects, abnormal heating | Machine damage, fire |

| Extremely flammable materials | Burns immediately during processing | Fire |

| Fluorine-based materials (PTFE, etc.) | Generates toxic gas when heated | Toxic gas generation |

⚠️Special caution: Handling transparent plastic sheets (unknown identity materials)

Commercially available and online “transparent plastic sheets” may contain chlorine-based materials such as PVC (polyvinyl chloride), and laser processing generates toxic hydrogen chloride gas.

- Transparent plastic sheets of unknown material must absolutely not be processed.

- Toxic gas can cause health damage (respiratory disorders) when inhaled.

- Hydrogen chloride gas corrodes metal parts and machine interior, clouds lens and mirror, greatly reducing processing accuracy.

Always check manufacturer, product number, material indication, and process only “chlorine-free” materials. “Unknown = Do not use” is correct.

Safety After Processing

⚠️Responding to Material Heat

- Materials are hot immediately after processing. Do not touch with bare hands.

- Wait at least 1-2 minutes after processing completion before touching material. Especially cut surfaces have high temperature, so be careful.

⚠️Continuing Exhaust and Removing Material

- Even after processing ends, keep exhaust fan operating for a while.

- Wait until smoke generated during processing is completely exhausted.

- When removing material, touch only after smoke completely clears and at least 1-2 minutes have passed.

Daily Maintenance and Safety Checks

Regular Cleaning

⚠️Cleaning Lens and Mirror

- When dust or dirt adheres to lens or mirror, laser reflection becomes unstable, causing fire.

- Clean regularly with dedicated cleaner.

⚠️Checking Exhaust Duct

- If exhaust duct is clogged, smoke flows back and fills room.

- Regularly check inside duct and remove dirt and debris.

Pre-Processing Checks Every Time

Check the following items before processing:

- Fire extinguisher position confirmation: Is it within reach?

- Exhaust function operation confirmation: Is it exhausting properly?

- Processing bed cleaning: Are there residues from previous processing?

- Material confirmation: Is it processable material, did you check indication?

- Surrounding safety confirmation: Are there no combustibles nearby?

Emergency Response

If Fire Occurs

- Stop machine immediately: Press STOP button

- Extinguish with fire extinguisher: Extinguish immediately if small fire

- Evacuate if fire is large: Don’t force extinguishing, call 119 and evacuate

- Ventilate: After fire is out, ventilate sufficiently

If Toxic Gas Generates

- Stop machine immediately

- Maximize ventilation: Open windows, maximize exhaust fan

- Leave the area: Go outdoors immediately to avoid inhaling gas

- See medical facility if unwell: If breathing difficulty, dizziness, nausea, see doctor immediately

Summary: Enjoy Laser Processing with Safety First

Laser cutters are very convenient and fun tools if safety rules are followed. However, a moment’s carelessness can lead to fire or health damage.

3 Points That Must Be Followed

- Never leave machine during processing

- Never use prohibited processing materials (especially PVC)

- Keep fire extinguisher ready and understand emergency response

By thoroughly following these, you can have a safe and comfortable laser processing life.