Laser Machine Development

CO2 Laser Machine Development

In February 2024, FabLab Westharima planned, designed, and manufactured an original CO2 laser machine and delivered it to Rokkosan Creative Lab!

- Video:

- Laser machine operation demo

1. Machine Specifications

| Machine spec | Description |

|---|---|

| Compatible Materials | MDF, wood, rubber, cork, plastic, paper, leather (Note: Excluding prohibited materials) |

| Work Area | Approx. 900 mm(w) x 600 mm (L) |

| Controller | RuiDa Controller |

| Control Software | RUIDA RDWorks Software, LightBurn |

Prohibited Materials

| Prohibited Material | Examples | Hazards |

|---|---|---|

| Chlorides | PVC boards, PVC pipes, PVC sheets, etc. | Toxic gas generation, machine damage (rust) |

| Mirrors/mirrored surfaces | - | Laser reflection damages machine Risk of blindness and injury |

| Highly flammable materials | Gunpowder, highly flammable materials (spray cans, batteries, paints, etc.) | Fire and explosion hazards |

| Fluorine-containing materials | Tapes, rubber sheets, etc. | Toxic gas generation |

2. Developer

Kazunari Takeda

- Role: Overall production, mechanical/electrical/control design and fabrication

- Background: Mechanical Engineer

- Previous Positions:

- Mitsubishi Electric Engineer

- RIKEN (Harima) (SPring-8) Engineering Team

- Current Position: Digico, LLC CEO & FabLab Westharima Founder

3. Parts Procurement

| Title | Where to purchase |

|---|---|

| Mechanical Parts | MISUMI |

| Mechanical (Custom Parts) | MISUMI Meviy |

| Electrical/Control Parts | AliExpress, VITAL system, HICON, GECKODRIVE |

4. Build Process

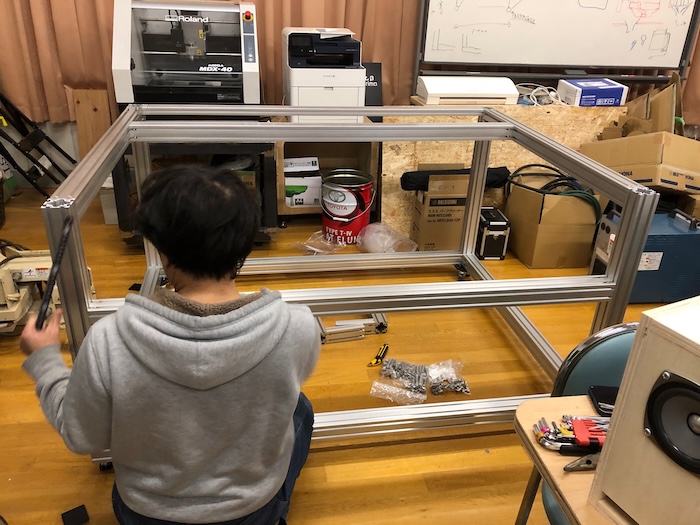

1. Frame Assembly

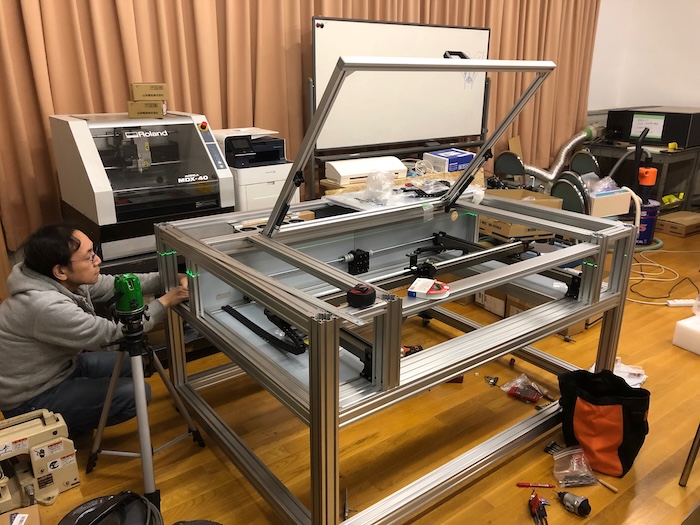

2. Laser Installation

3. Electrical Components and Air Ports Installation

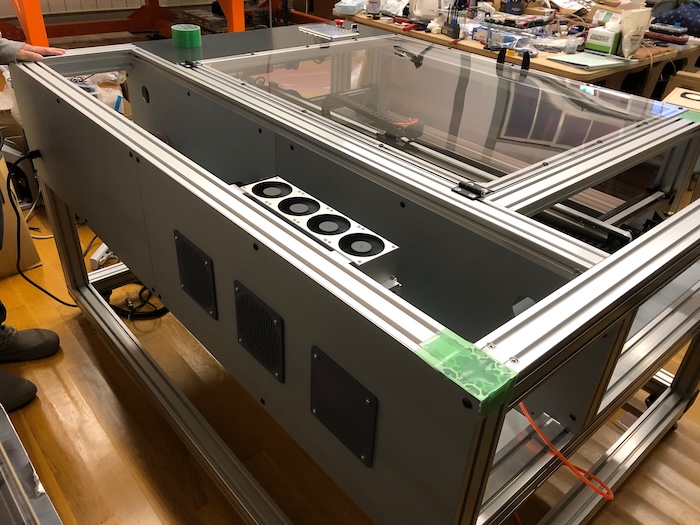

4. Controller and Emergency Stop Button Installation

5. Surrounding Panel Installation

6. Laser Beam Angle Adjustment

7. Laser Beam Test

8. Completion

5. Processing Tests

Engraving (Material: Wood)

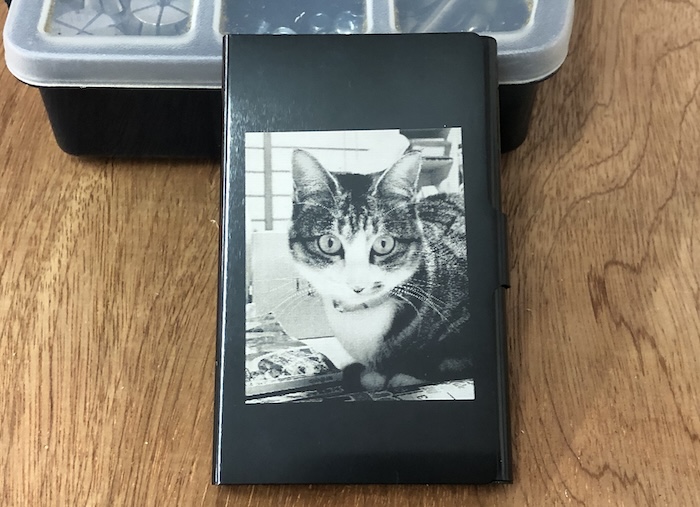

Engraving (Material: Anodized Aluminum)

Cutting (Plywood 5mm thickness)

You can view the actual cutting process in video format.

Safety Features

- Cooling system equipped

- Exhaust system

- Emergency stop function

- Interlock mechanism

Designed with safety in mind, achieving high-quality processing results.