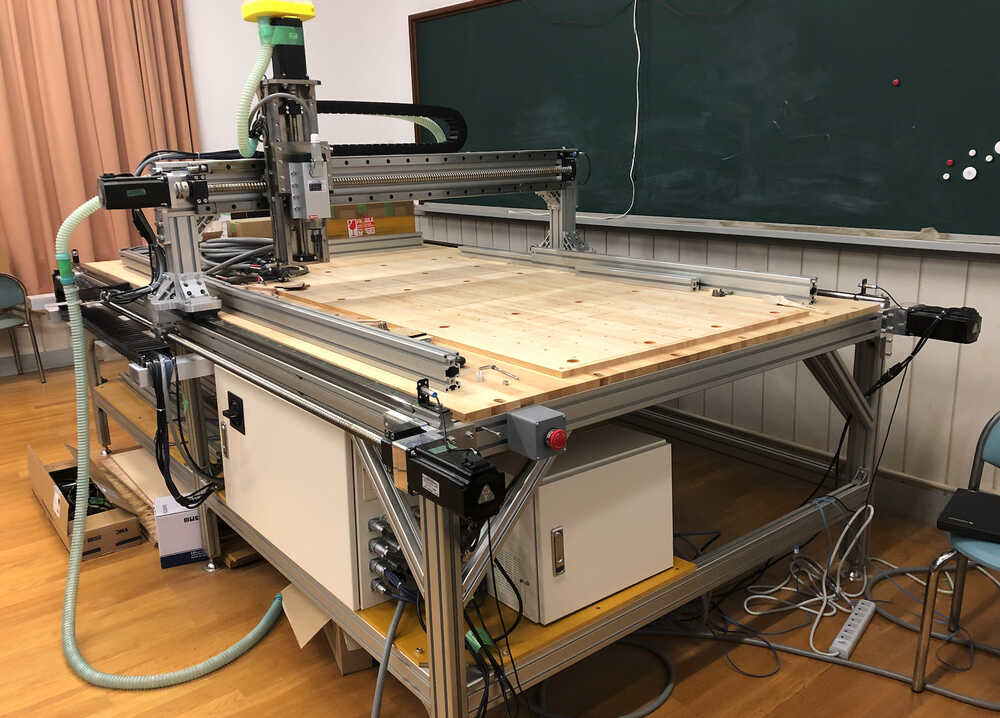

CNC Machining Development (Digico-MILL48)

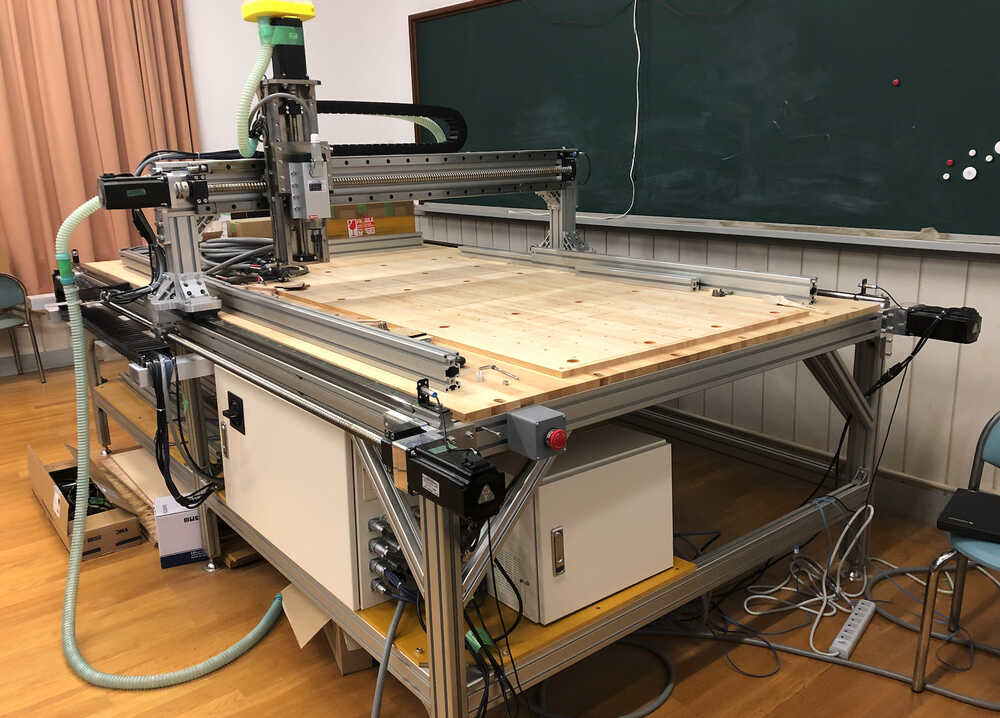

Digico-MILL48 is a completely original CNC machining center that was planned, designed, manufactured, and installed by the founder of FabLab Westharima and his friends. Since building the first unit in 2020, we have continued to develop and manufacture it with ongoing improvements.

1. Digico-MILL48 Version 1

1-1. Machine Specifications

| Machine spec | Description |

|---|---|

| Compatible Materials | Wood, machinable materials (acrylic, polycarbonate, PVC, etc), aluminum |

| Work Area | Approx. 1300 mm(w) x 2500 mm (L) x 150 mm (H) |

| Feed rate | 1-3000 mm/min |

| Spindle speed | max 18000 r/min |

| Control Board | HICON Integra mill |

| Control Software | Mach4 |

1-2. Developers

Kazunari Takeda

- Role: Overall production, mechanical/electrical/control design and fabrication

- Background: Mechanical Engineer

- Previous Positions:

- Mitsubishi Electric Engineer

- RIKEN (Harima) (SPring-8) Engineering Team

- Current Position: Digico, LLC CEO & FabLab Westharima Founder

Takayuki Mimura

- Role: Mechanical design, parts machining, assembly and adjustment

- Background: Mechanical Engineer

- Previous Position: RIKEN (Harima) (SPring-8) Engineering Team

- Current Position: Proto Design Inc. Engineer & Executive

Kenta Ishino

- Role: Mechanical design, assembly, and adjustment

- Background: Mechanical Engineer

- Previous Position: RIKEN (Harima) (SPring-8) Engineering Team

- Current Position: Glory Technical Solutions Engineer

*Mimura and Ishino are FabLab Westharima operational collaborators

1-3. Background of Original CNC Development

- Initially planned to purchase a ShopBot (abandoned due to subsidy rejection)

- After seeing the actual ShopBot, felt it could be built independently

- Considered creating an original CNC machine

- Three developers (Takeda + 2 friends) identified structure and component requirements (referencing open-source machines like ShopBot, Avid CNC)

- The three developers had specific requirements:

- Wanted all XYZ axes to use linear rails and ball screws

- For Y-axis, wanted a 3m-long linear rail and ball screw without joints

- Started searching for manufacturers, ordered from Chinese manufacturer and imported

- Wanted to use metric screws and bolts (not imperial) (because metric is easier to obtain from tool shops in Japan)

- Joints and mounting brackets were custom-designed by Takeda and machined by Mimura

- Wanted to use electrical and control components slightly better than those used in ShopBot and Avid CNC

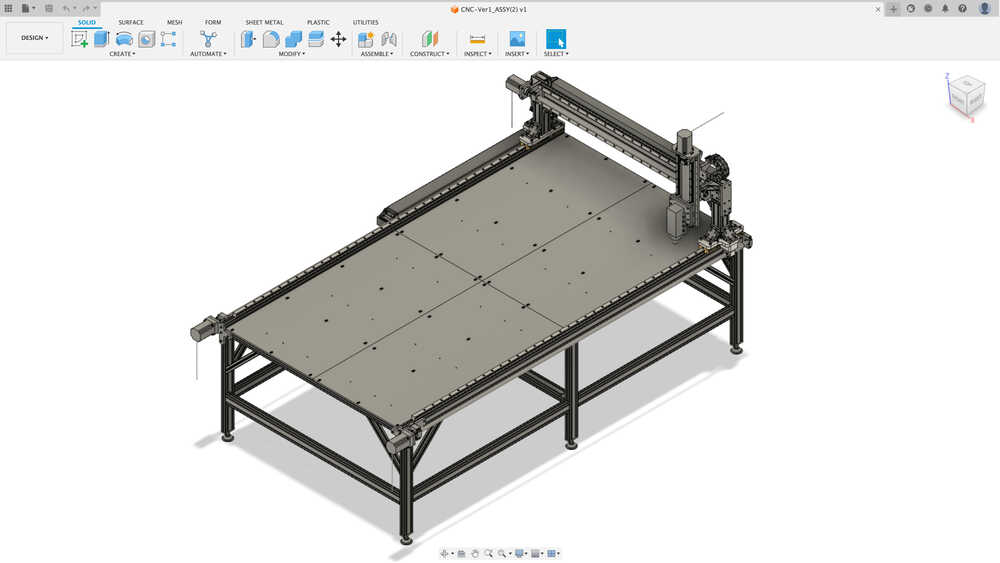

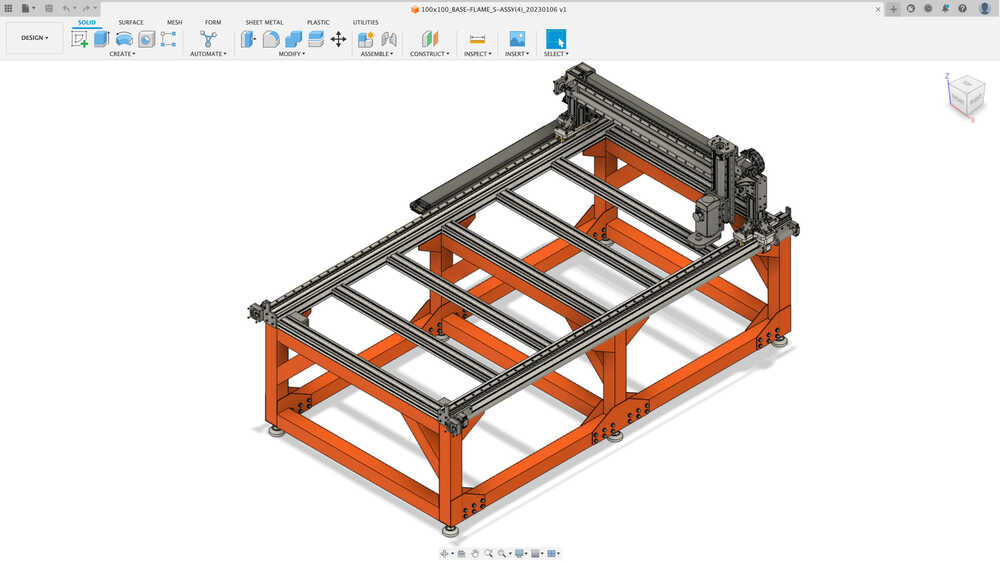

1-4. Design Software

- Designed in Fusion360 (CAD)

1-5. Control Board

![]()

1-6. Parts Procurement

| Title | Where to purchase |

|---|---|

| Mechanical Parts | MISUMI |

| Custom Parts | Proto design, MISUMI Meviy, FabLab Westharima in-house (3D printer fabrication) |

| Linear Guides & Ball Screws | Imported from Chinese manufacturer |

| Electrical Components | AliExpress, VITAL system, HICON, GECKODRIVE |

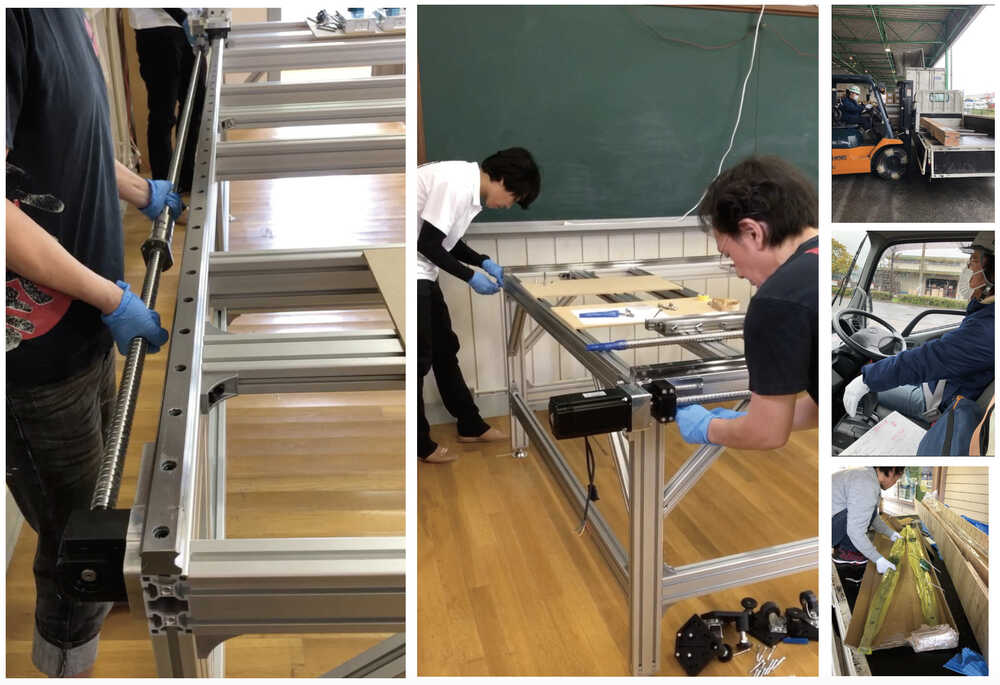

1-7. Build Process

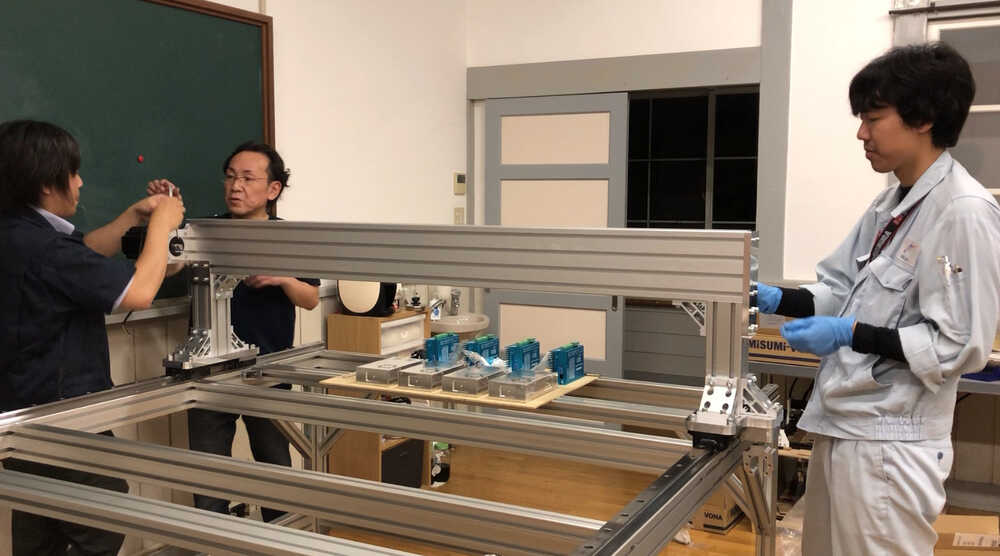

First, assembling the base aluminum frame. Members from FabLab Kobe also helped.

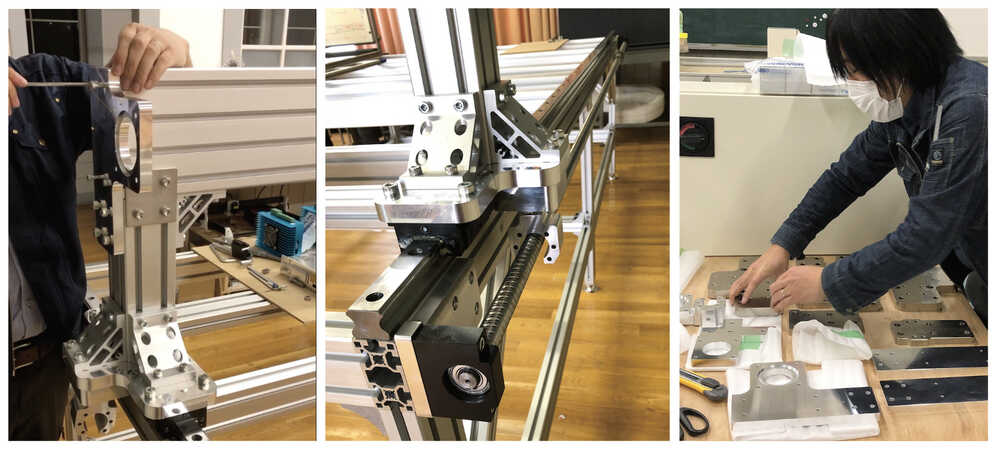

Installing linear rails and ball screws.

The 3m linear rails and Y-axis ball screws were imported from a Chinese manufacturer via sea freight, going through customs procedures and large-scale X-ray inspection. This was a valuable experience.

Mounting the gantry was challenging work, as each part was heavy and the weight increased with each assembly step.

Custom parts were used for joints.

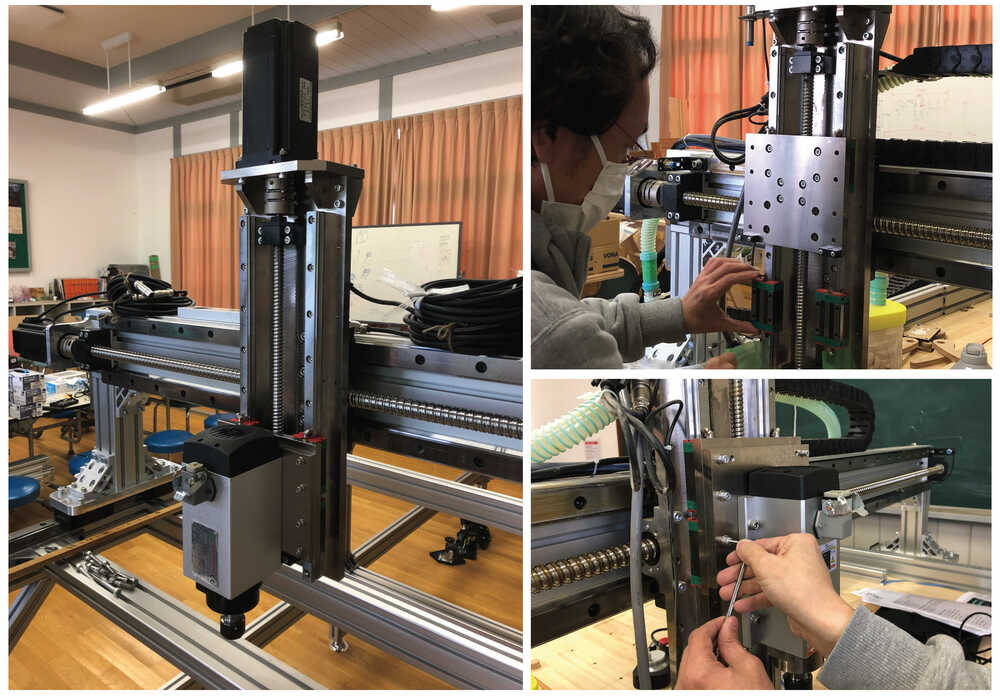

Installing the Z-axis. Metal part assembly required precise positioning and was difficult due to the heavy weight.

Wiring work. Being a large machine, wiring for motors and sensors was long and required significant time for preparation.

Connecting wiring to the distribution panel.

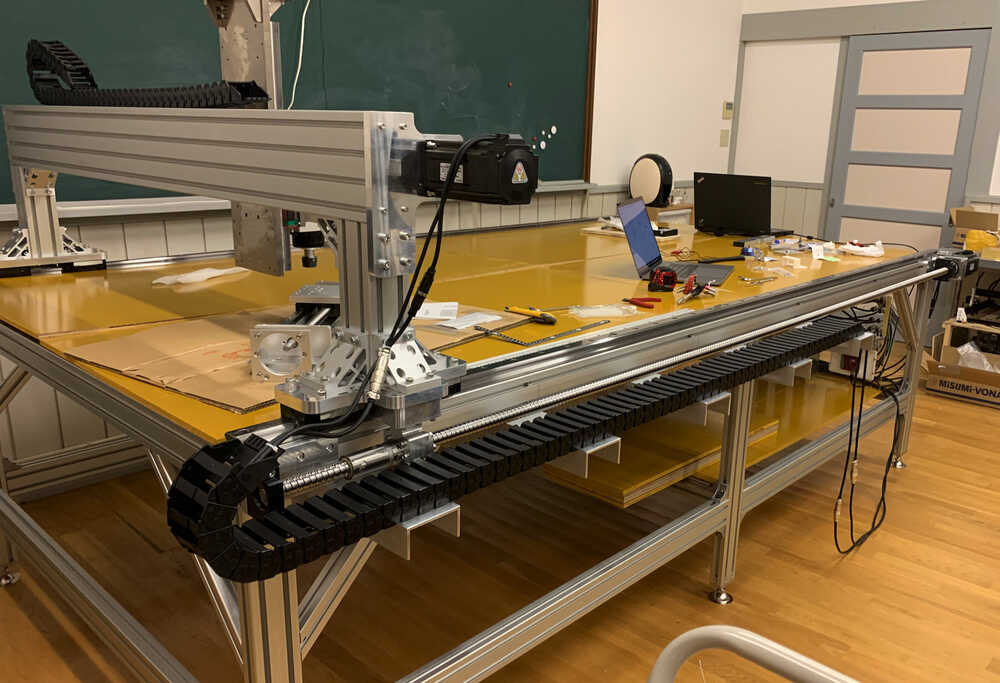

Machine fabrication complete, test run successful. We are satisfied with our first completely original machine, from planning, design, fabrication, to installation.

1-8. Test

Table and chair making - Success!

1-9. Making Video

Making, CNC Machining Version 1, build from 2020, 29 JAN to 15-OCT

1-10. Machine Upgrades

The first model was built similarly to Avid CNC, which we respect, but since then we have continued upgrading, improving structural and mechanical aspects that could affect precision and strength, and enhancing usability, following ShopBot and Avid CNC as models.

| Version | Development |

|---|---|

| 1 | Build Avid CNC-like original CNC |

| 2 | Improved adjustment mechanisms throughout (especially Z-axis and spindle) |

| 3 | Changed frame to 80x80 aluminum frame |

| 4 | 80x80 steel frame and steel conversion of various parts |

| 5 | 100x100 steel frame, improved Z-limit reliability |

2. Digico-MILL48 Version 5

- 2022-AUG 23 to 2023-MAR-12

- CNC Machining Version 5 Steel Frame

- We also performed the welding ourselves, completing a heavy-duty, robust CNC machining center that doesn’t budge even during processing vibrations.

- When FabAcademy2023 admission was confirmed at the end of 2022, we rushed production. We managed to complete it in time for Week 7 “Computer-Controlled Machining,” and had an auspicious start with the individual assignments (make something big) of two students being the first machining projects.

Making, CNC Machining Version 5 (100x100 Steel Frame model), build from 2022-AUG 23 to 2023-MAR-12

3. Digico-MILL48 Version 6

In 2023, we collaborated with students and faculty from Kobe Design University (KDU) to jointly produce CNC Machining Version 6. With excellent precision and finish, we completed a machine we’re very proud of!